Vertical Straight Line Beveling Machine

Specifications

Glass Machine

1.10 wheels with pneumatic polishing

2.Simple controll

3.Front beam hoit

Glass Machine

1.10 wheels with pneumatic polishing

2.Simple controll

3.Front beam hoit

1. Thanks to pneumatic adjusting for polishing wheel, the machine can polish glass with fine and clear surface.

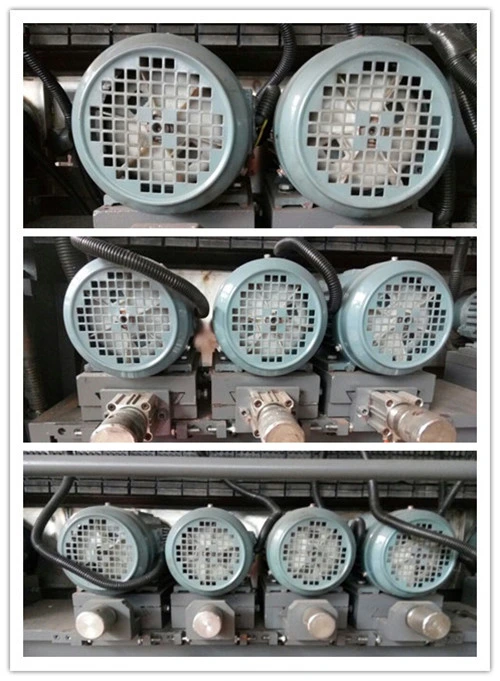

2. Adopt pneumatic polishing system, synchronic belt & high precision, stable electric motor;

2. Adopt pneumatic polishing system, synchronic belt & high precision, stable electric motor;

3. Manual, single chip, PLC control system for option;

4. High efficiency, high quality, stable running & simple operation.

Here are the basic information:

Module: YD-BM-10

A. Wheel number: 10pcs

B. Power: 23.5KW

C. Weight: 3500kg

D. Pressure: 6kg/cm2

E. Glass thickness: 5-19mm

F. Bevel angle: 3-30 degree

G. Max. bevel width: 35 mm

H. Glass speed: 0.8-3 m/min

I. Min. Glass size: 30x30mm

J. Out dimension: 7.2x1.2x2.6m

K. Compress air consumption: 1It/min

A. Wheel number: 10pcs

B. Power: 23.5KW

C. Weight: 3500kg

D. Pressure: 6kg/cm2

E. Glass thickness: 5-19mm

F. Bevel angle: 3-30 degree

G. Max. bevel width: 35 mm

H. Glass speed: 0.8-3 m/min

I. Min. Glass size: 30x30mm

J. Out dimension: 7.2x1.2x2.6m

K. Compress air consumption: 1It/min

Main Technical Specification:

| Model Number | YD-BM-9 | YD-BM-10 | YD-BM-10S | YD-BM-10-45 | YD-BM-11 | YD-BM-13 |

| Total nr.of spindle | 9 | 10 | 10 | 10 | 11 | 13 |

| Glass thickness(mm) | 5~19 | 5~19 | 5~19 | 5~19 | 5~19 | 5~19 |

| Min.glass size(mm) | 150×150 | 150×150 | 30×30 | 150×150 | 150×150 | 150×150 |

| Bevel angle(degree) | 3~30 | 3~30 | 3~45 | 3~30 | 3~30 | 3~30 |

| Max.bevel width(mm) | 35 | 35 | 35 | 35 | 35 | 35 |

| Glass speed(m/min) | 0.8~3 | 0.8~3 | 0.8~3 | 0.8~3 | 0.8~3 | 0.8~3 |

| Compressed air Consumption(It/min) | <1 | <1 | <1 | <1 | <1 | <1 |

| Power(kw) | 21 | 23.5 | 25 | 23.5 | 25 | 30 |

| Outer dimension(m) | 7.0×1.2×2.6 | 7.2×1.2×2.6 | 7.2×1.2×2.6 | 7.2×1.2×2.6 | 7.2×1.2×2.6 | 8.0×1.2×2.6 |

| Weight(kg) | 3000 | 3500 | 3500 | 3500 | 4000 | 4500 |

Beveling machine:

- One year guarantee for whole machine.

- 24 hours technical support by e-mail.

- Ues-friendly English software,user manual and detailed Videos/CD.

We will provide all spare parts needed for maintenance of the equipments.

Professional after-sales service team support face-to-face training and installation to customer's factory.

Why choose Ladglass?1. Widely used in different industry

2. High precision and reputation

3. CE Certificate High quality parts

4. Competitive price

5. Fast delivery

6. Best service